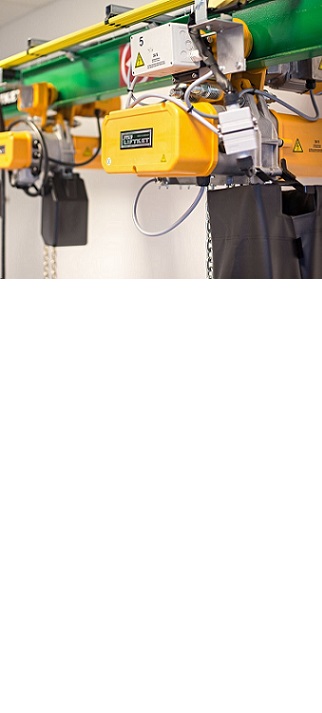

Our electric chain hoists are designed and built in Germany using only the highest quality European components.

With more than 60 years of experience in the design and manufacture of electric chain hoists our range has many features as standard that other manufacturers only offer as extras.

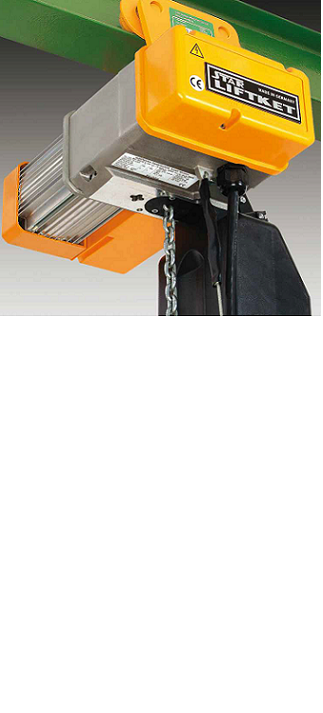

Unique Safety-Brake System

All hoists incorporate a unique safety-brake system. In this system the clutch is located between the motor and brake in such a way that the brake will continue to hold the load safely in the unlikely event that either the clutch or motor fails.

Also due to the compact design of our range of hoists headroom is kept to a minimum to provide the maximum lift height. In addition running noise is kept low due to the use of helical gears made from the highest quality of alloy steel.

The Liftket name is well known in all industrial countries around the world and the name stands for modern electric chain hoists with lifting capacities from 125kg up to 25 tonnes.

Special advantages.

- Precision machined sprocket wheel.

- Lightweight aluminium housing.

- Modular construction for ease of repair.

- High duty cycle (up to 60%)

- Class F insulation.

- Upper and lower limit switches.

- Heat treated helical gears made from high quality steel.

- Low maintenance DC break ensuring positive activation.

- Patented safety clutch - brake system with asbestos free linings.

- Low voltage controls complete with emergency stop.

- IP55 rating as standard (protection from water and dust).

- High quality zinc plated load chain fitted to all models.

- Designed and manufactured in Germany using only the highest quality components.

- Top hook suspension (low headroom couplers on request).

- Hoists can be changed from single to a double fall quickly and easily.

- Used in a large percentage of Wind Turbines worldwide.

- Single fall capacities to 12.5 tonnes.