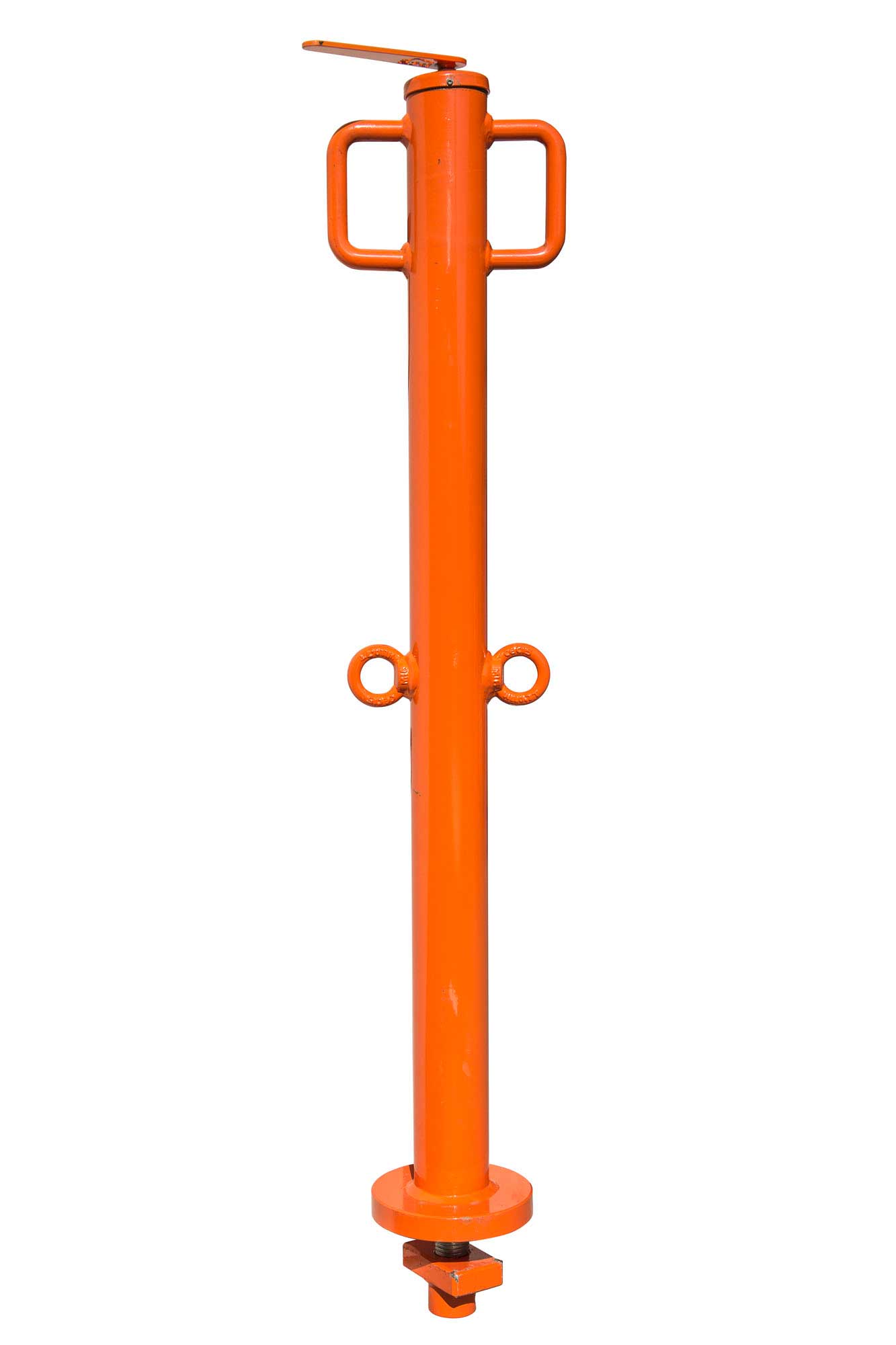

The BTS Shipping Container Anchor Post (SCAP) is designed to provide a limited free fall arrest system for working on top of a 20ft or 40ft shipping container.

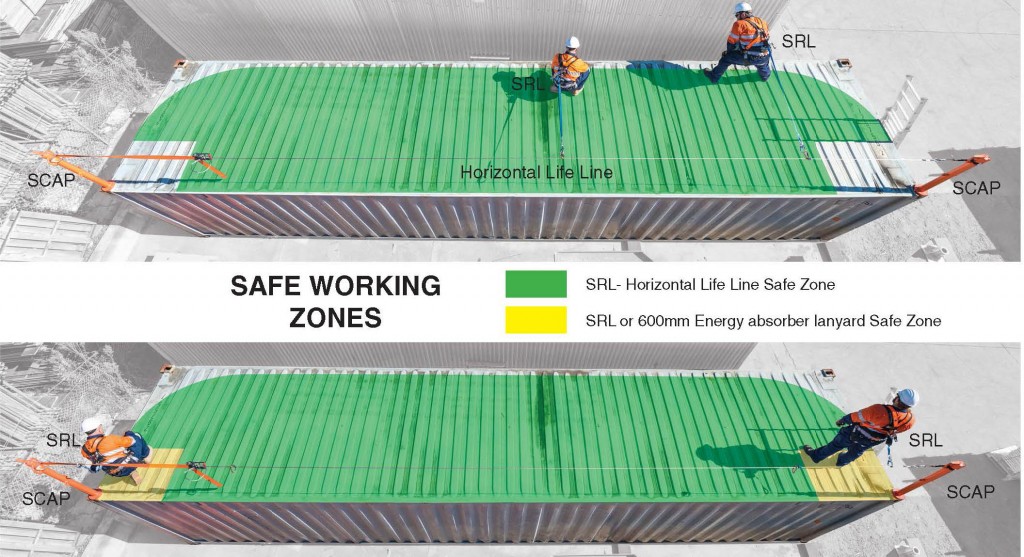

SCAP can either be used on its own as a limited free fall arrest anchor or in conjunction with a Horizontal Lifeline System (HLS) depending on the demand of the work being carried out on the container.

The anchor post is designed to utilize the corner castings on the container as the installation point for the system.

There are restrictions and limitations that must be carefully considered in the selection, installation and operation of this equipment.

BTS Product Code: CBPOST18KN

Shipping Container Anchor Post (CBPOST18KN) – dynamically tested to 18kN as per section 6.3.2.2 of AS/NZS5532:2013 and statically tested to 18kN as per section 6.3.1 of AS/NZS5532:2013.

SAFE WORKING ZONES for SLR-Horizontal Life Line and SLR or 600mm Energy absorbing lanyard.

Installation of the Shipping Container Anchor Post Kit

The SCAP are installed by inserting the bottom of the post into the corner casting of the shipping container. Using the lever on top of the post, (turn anti-clockwise to tighten), adjust the locking nut in the container casting such that it sits perpendicular to the opening slot of the cast.

|

|

|

|

|

Before using the SCAP, the user needs to be equipped with appropriate PPE and a full body harness compliant to AS/NZS1891.1.

An SRL shall be attached to the SCAP personnel attachment point which gets attached to the harness of the user.

When working close to the edge of the container, the worker shall not be further than 600mm of the installed anchor point. This is the safe working zone to prevent a pendulum effect from occurring in case of a fall.

Horizontal Lifeline System

The Horizontal Lifeline System is installed by setting up two Shipping Container Anchor Posts on either corner of a long side of the container and connecting the wire rope kit (LIFELINEKIT-20A or LIFELINEKIT-40B) using a polyester tie off strap and karabiner on one side and ratchet and webbing strap on the other. The wire rope is tensioned using the ratchet.

Prior to using this system, the user needs to be wearing a full body harness (compliant to AS/NZS1891.1) and connected to the Horizontal Lifeline System using an SRL.

The Horizontal Lifeline System is dynamically tested as an assembly with the CBPOST18KN to 18kN as per Appendix D of AS/NZS1891.2:2001 and statically tested as an assembly with the CBPOST18KN to 12kN as per Appendix E of AS/NZS1891.2:2001.

AVAILABLE KITS (FOR 20FT AND 40FT CONTAINER)

Additional parts recommended but not included in the HLS Kit

|

| 2 x BTECH full body harness compliant to AS/NZS1891.1. |